OTSCON: No Stopping Them

In eastern Boone County, at the intersection of two quiet roads, sits a white warehouse. It’s austere for the most part, an outbuilding of sheet metal next to acres of open farmland. The intertwining streets are called Richland and Rangeline, two fitting names for this mid-Missouri swath of rural panorama.

The facility, however, is anything but serene. Inside, approximately 200 employees are focused on making sure the Japanese car you might be driving has the ability to slow and stop at your whim.

OTSCON (pronounced “Oats-Con”) is one of more than a dozen businesses loosely cobbled together in an industrial park four to five miles east of Highway 63 and just south of I-70. The firm manufactures parking brake systems across North America for Honda, Nissan, Subaru, Toyota, Acura, and Infiniti.

The company began in 1988 as a joint venture between the Otsuka Koki Company, of Yokohama, Japan, and Orscheln Industries, of Moberly. The name is derived from a combination of the two firms. Orscheln liked the “CON” suffix for several of its other ventures, and Otsuka tacked on the first three letters.

Their Detroit office sold the company’s products until 1993, when OTSCON moved to Columbia. In 1996, the Japanese firm bought out Orscheln’s interest. Otsuka Koki Ltd. is now the parent company for 10 other firms in eight different countries.

Over the past 20 years, OTSCON has experienced five local expansions, and Kathy Cowan-Smith, plant manager, has seen them all. She’s used to change and prefers the rapid pace. “Automotive manufacturing is a constantly changing field,” she says. “It’s completely different than what I did before,” referring to her previous days in the production of carpet-laying materials.

Working for an international firm like Otsuka Koki means a penchant for production. “Japanese automakers have a culture of open communication regarding goals,” Cowan-Smith says. “They are well posted, and we have a lot of quality benchmarks.”

The OTSCON facility encompasses a little over 200,000 square feet and specializes in braking systems that include brake pedals and foot pedal emergency brakes, cane brakes (for commercial trucks, for example), and center-lever emergency brakes (the hand brake between your front seats).

“Automotive manufacturing is a constantly changing field.” — Kathy Cowan-Smith

“I’d say we make an average of 45,000 to 55,000 products a week,” Cowan-Smith says. That’s a hefty supply of parts leaving Columbia, and it requires a complex set of skills in the production process, ranging from stamping, welding, milling, heat treating, injection molding, assembly, and inspection. The plant also employs five individuals in research and development, designing and testing new products.

Cowan-Smith points to the recent application of robotic welding, stamping, and injection mold capabilities as some of the company’s finest achievements. Another accomplishment was snatching Toyota as a customer. Previously, OTSCON had been a tier two supplier to the Japanese automaker, but they moved to tier one status approximately five years ago; the upgrade meant that OTSCON became a direct supplier of parts sold by Toyota straight to the consumer. Specifically, the local plant makes emergency brakes for the Toyota Camry. They also provide brake pedals for Subaru and braking systems for the Honda Civic and Nissan Altima, among many other vehicles.

The company has expanded into the automotive brake pedal business at the Columbia plant, but they also have a new venture to occupy their time: managing a startup with folks from down under.

At the end of January 2016, OTSCON entered into a joint endeavor with Australia’s MTM Automotive Components. The new company, MTM-OTSCON, will be headquartered within the Columbia plant. The undertaking came from a chance meeting between MTM’s owner and OTSCON vice president Satoshi Watanabe. “They had some acquaintances in common, and MTM has wanted to expand into the North America market,” Cowan-Smith says.

The company will start off with around 25 employees or so in the first three years and then expand, according to Cowan-Smith. “Within the next five years, we hope to grow MTM-OTSCON to the point that we can build a separate facility for them in Columbia or along the auto corridor,” she says. That corridor is defined by their Japanese parent company as Mideast states like Ohio, Kentucky, and Tennessee.

MTM-OTSCON will likely manufacture door components and similar elements. “We’re putting out a lot of different feelers on types of parts, but we know at least they’ll all be for the automotive industry,” Cowan-Smith says.

OTSCON faces the same trials as other manufacturers in the industry: adapting to ongoing changes in technology and consumer preferences, and the search for new customers. For OTSCON, that means finding and securing clients for brake pedals, clutches, and accelerators.

“The biggest challenge is breaking into a new product line,” Cowan-Smith says. “But we’re up to it. We’ve been a part of this community for over 20 years, and our intention is to be here for many more to come.”

After two decades, it’s clear that while this Columbia business specializes in helping people reduce speed, they don’t plan to put the brakes on their success anytime soon.

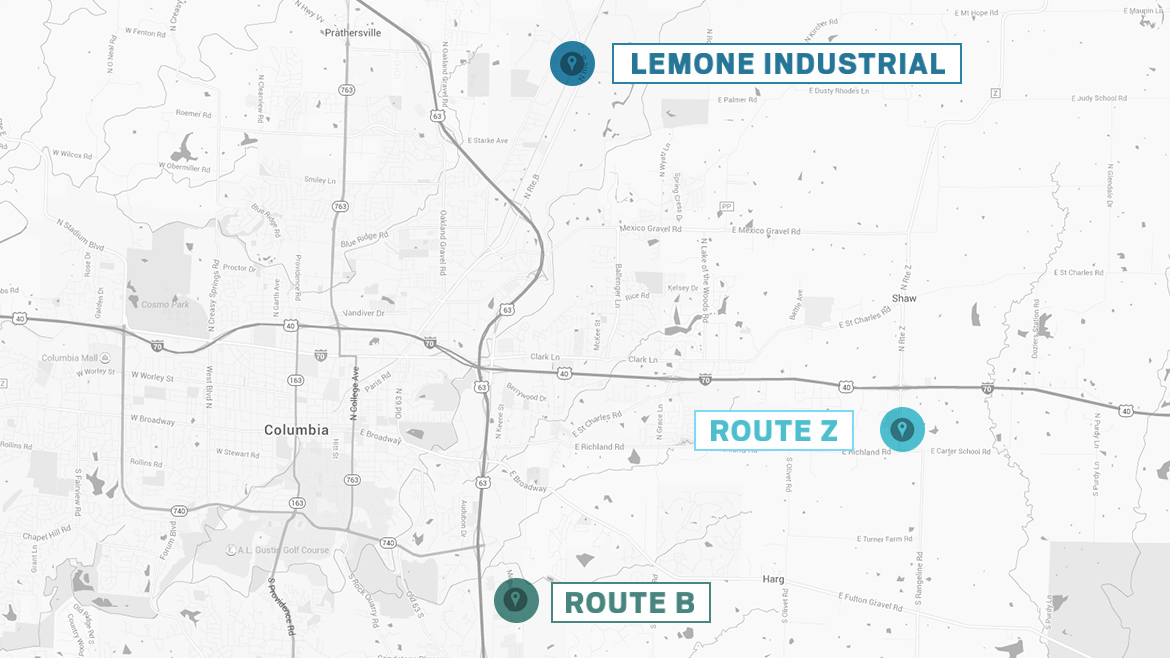

Columbia’s Industrial Parks

Lemone Industrial

- Linen King Group LLC

- Perry Legend Collision Repair

- Marine Parents

- OATS

- IBM

- CARFAX Inc.

- Bryan University

- Courtyard Marriott

- Ryder Truck Rental and Leasing

- United States Postal Service

- MU Assessment Resource Center

- ABC Supply Co. Inc.

- Coca-Cola

- Dana Limited

- FedEx Ground

- Battenfeld Technologies

- Gates Rubber

- Quarterdeck Building – MU Health Care

- Allstate Consultants

- Dialysis Clinic Inc.

- Missouri Crop Improvement Association

- Goedecke Construction Equipment and Supplies

- MU Printing Services

- Daily Living Medical

- Industrial Textiles

- Ameren UE Training Center

- MU Libraries Depository

- Data Retention Services

- MU Supply Chain Records Management

- CenturyLink

- Veterans United Home Loans

Route Z

- OTSCON INC.

- Chigger Creek Wood Products

- Elevate Gymnastics and Fitness

- Copart Auto Auction

- Missouri Auto Auction

- YRC Freight

- Wildcat Materials

- Cintas Uniform Services

- Estes Express Lines

- CMC Manufacturing (Central Missouri Countertops)

- Capital Railroad Contracting (RR & Excavation)

- Precision Precast

- Statler Stitcher

- Pertech

- Kelley Klean Restoration Company

- AsCon Construction

Route B

- Environmental Dynamics International (EDI)

- FedEx Freight

- Engineered Plastic Components

- Johnson Products

- Cell-Pak

- Tractor Supply Co.

- Quaker Oats

- Henderson Implement and Outdoor Power

- Broad Building Supply

- Honeywell

- JM Eagle

- Schneider Electric – Square D

- 3M

- Kraft Heinz

- Kelly Services

- Triple L Mini Storage

- Nauser Beverage

- Glazer’s Midwest

- Con-Way Freight

- Mid-City Lumber

- American Air Filter

- Weaver Manufacturing