Environmental Dynamics International: Wastewater Worldwide

Without Columbia firm Environmental Dynamics International, something wouldn’t smell right in China.

That’s because their products are used in what happens to be the world’s largest wastewater treatment system, handling more than one billion gallons of sewage a day in that country.

Chuck Tharp is the chairman and co-founder of EDI, a designer and manufacturer of city and industrial sewage treatment products distributed globally. EDI has put up some impressive numbers in the industry, raking in more than $30 million in annual sales, with nearly 7,000 installations in 105 countries. In fact, more than 300 million people worldwide — or roughly the same number of people living in the entire United States — benefit from EDI’s equipment.

Even though EDI possesses a massive global footprint, you won’t find them in Columbia’s top 10 largest employers list. They currently max out at around 100 workers. Still, it’s a far cry from the simpler days, when Chuck and his cousin, Clark Campbell, started in 1976.

Campbell ran a plumbing company at the time, and Tharp was putting his civil and environmental engineering degrees to use in waste treatment equipment for larger plants. EDI began selling smaller systems to area municipalities, originally with meager but positive results. First year sales were approximately $24,000.

“The economy and other issues made it attractive to expand our horizons,” Tharp says. They saw an opportunity where most did not, taking science and fitting it into real-world needs. “It’s not so much inventing new technology as it’s applying technology to current problems,” he says.

Specifically, Tharp patented a system that configured high-efficiency devices for aerating lagoons. The result was a gain in energy savings by as much as 50 percent over existing technology; that became EDI’s secret sauce: selling equipment on the basis of energy efficiency.

“Biological and aeration systems were the key,” Tharp says. The basic principle is that bacteria are needed to consume waste. For bacteria to grow and multiply, they need oxygen, which is added to water in a process known as aeration. The byproduct of aerobic biological treatment is carbon dioxide and water, which are odorless. Without oxygen, a different kind of bacteria (anaerobic) multiplies instead, releasing the familiar sewer smell.

“Biological and aeration systems were the key.” — Chuck Tharp

Encouraged by their results, EDI continued to apply scientific solutions aimed at large-scale needs. In 1993, the company moved to its current location at 5601 Paris Road. The 110,000-square-foot facility sits on about 11 acres and includes manufacturing, engineering, a small research park, and two laboratories.

EDI has grown exponentially. Just over half of their business is now beyond U.S. borders. They have operations in China, Singapore, Germany, Japan, India, the U.K., and Mexico. About 70 percent of their clients are subdivisions and municipalities, including the City of Columbia. About 30 percent of their customers are industrial, such as meat-packing plants, wineries, and fracking operations.

But with growth comes complexity, and a few more headaches. Not that Tharp minds the company’s success. He takes great joy in EDI’s ability to help put food on the table for the 100-plus families who work there, but things are a lot different than they were 40 years ago. Before, EDI only had to solve the problems of small-town America.

“Back then, my ambition was to grow to a million dollars in sales, and then I was going to be rich,” Tharp says. “We have $30 million in sales now, and I guess I’m still waiting to be rich.” That’s because Tharp and his leadership team, dealing with international trade, must consider tariffs, foreign exchange rates, the nuances of regulation and compliance, and numerous expenses. In addition, every CEO must contend with pressure from competitors — for EDI, they would be Xylem, out of New York, and French giants Veolia and Suez.

Running a business that touches the other side of the world requires the capacity to adapt quickly and hire the right talent at the right time. For example, EDI had been doing only modest business in the Middle East until they hired an individual in Dubai who spoke Arabic fluently. “We grew volume by a factor of four this year as a result,” he says. “After 40 years, EDI is still growing. You have to grow if you want to stay competitive.”

EDI recently incorporated a sister company — EDI India — to serve the India market. Tharp says the move avoided high shipping costs and large import duties, and it allowed for faster customer service. “Shipping from the United States took more than six weeks on the water, which led to missed opportunities,” he says.

At the time of this writing, EDI was about to incorporate an EDI Europe, in the U.K. “The European theater and Middle East are areas of great opportunity,” Tharp says. “They respect intellectual property rights, and we can be very competitive there.”

Tharp seems to take all the complexities in stride. Perhaps that’s because at the age of 77, he’s been around the lagoon more than most in the business. He attributes EDI’s continued success to sticking to its forte: innovation in aeration systems and biological treatment solutions.

“We basically have been a small company that has been able to carve out a niche in this business,” he says. “When you can do that, you’re able to sustain yourself. I’ve watched a lot of others get absorbed or fall by trying too much.”

EDI’s efforts at applied science likely stem from Tharp’s own discipline. His farm background, combined with an engineering degree, resulted in more than a few working concepts. “In high school, I had the idea that I wanted to build things, particularly things that could be put to use,” he says.

Today, EDI products are being put to use in thousands of projects on seven continents. EDI may not be the most familiar local brand, but they’ve been responsible for cleaning up a considerable part of the world — from right here in CoMo.

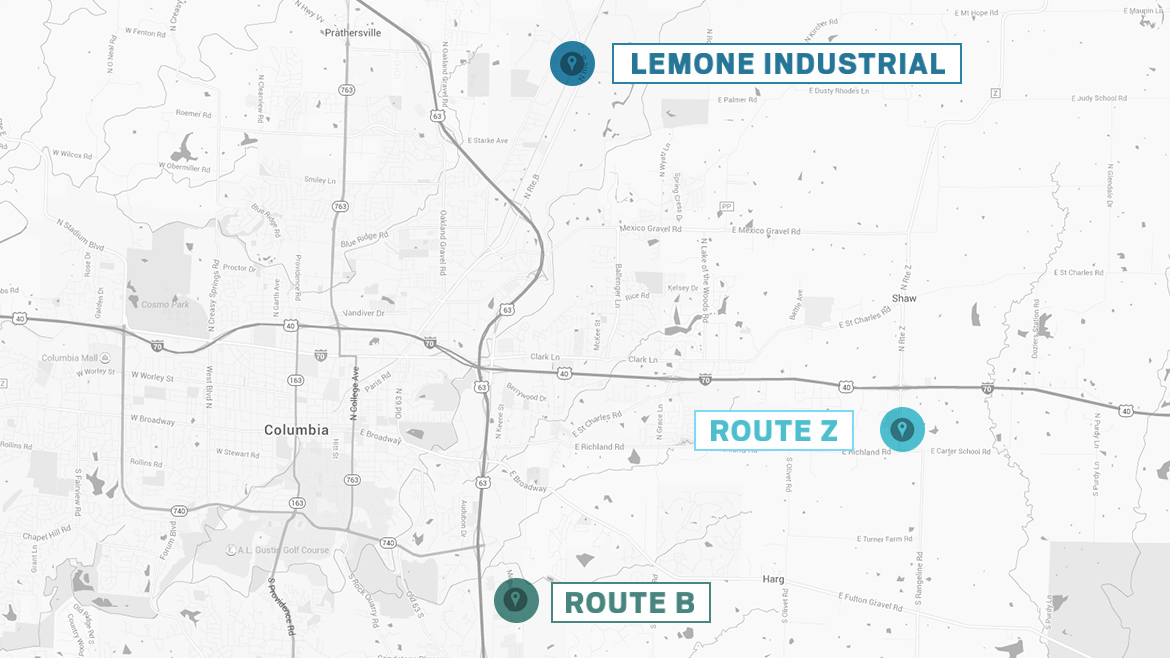

Lemone Industrial

- Linen King Group LLC

- Perry Legend Collision Repair

- Marine Parents

- OATS

- IBM

- CARFAX Inc.

- Bryan University

- Courtyard Marriott

- Ryder Truck Rental and Leasing

- United States Postal Service

- MU Assessment Resource Center

- ABC Supply Co. Inc.

- Coca-Cola

- Dana Limited

- FedEx Ground

- Battenfeld

Technologies

- Gates Rubber

- Quarterdeck Building – MU Health Care

- Allstate Consultants

- Dialysis Clinic Inc.

- Missouri Crop Improvement Association

- Goedecke Construction Equipment and Supplies

- MU Printing Services

- Daily Living Medical

- Industrial Textiles

- Ameren UE Training Center

- MU Libraries Depository

- Data Retention Services

- MU Supply Chain Records Management

- CenturyLink

- Veterans United Home Loans

Route Z

- OTSCON INC.

- Chigger Creek Wood Products

- Elevate Gymnastics and Fitness

- Copart Auto Auction

- Missouri Auto Auction

- YRC Freight

- Wildcat Materials

- Cintas Uniform Services

- Estes Express Lines

- CMC Manufacturing (Central Missouri Countertops)

- Capital Railroad Contracting (RR & Excavation)

- Precision Precast

- Statler Stitcher

- Pertech

- Kelley Klean Restoration Company

- AsCon Construction

Route B

- Environmental Dynamics International (EDI)

- FedEx Freight

- Engineered Plastic Components

- Johnson Products

- Cell-Pak

- Tractor Supply Co.

- Quaker Oats

- Henderson Implement and Outdoor Power

- Broad Building Supply

- Honeywell

- JM Eagle

- Schneider Electric – Square D

- 3M

- Kraft Heinz

- Kelly Services

- Triple L Mini Storage

- Nauser Beverage

- Glazer’s Midwest

- Con-Way Freight

- Mid-City Lumber

- American Air Filter

- Weaver Manufacturing