Made in Columbia

When Stephens College, the University of Missouri and Columbia College were established in Columbia in the mid-1800s, the city became known as a center of education. Columbia also became recognized for its health care institutions and insurance companies as those industries grew.

Standing strong in the shadows of education, health care and insurance have been Columbia’s manufacturers. Despite an impressive list of manufacturers who are part of Columbia’s economy, manufacturing seems to “fall under the radar,” says labor market analyst Randall Clark of the Missouri Department of Economic Development.

“Manufacturing has been a significant part of Boone County’s economy,” Clark says. “It tends to pay higher wages than service-providing industries.” Based on Clark’s research at Missouri Department of Economic Development, the average wage for the manufacturing sector in Boone County was $42,380, compared to $32,703 for the general average wage from the fourth quarter of 2010 to the third quarter of 2011.

With the number of manufacturing jobs now increasing in Missouri, economic experts like J. Michael Brooks, president of Regional Economic Development Inc. (REDI), are recognizing the value of manufacturing to the community. “For the industries that are just identified as education, health and insurance, most jobs require college education,” Brooks says. “Part of the focus, or importance, from our standpoint as we look at manufacturing are the job opportunities that it provides for citizens who don’t have a college degree.”

According to Missouri Economic Research and Information Center, the total number of manufacturing employment in Boone County decreased from 5,094 in 2004 to 3,174 in 2010. But last year manufacturing saw an increase of more than 400 jobs as the local economy began to recover from the recent recession.

“I do believe that we are going to experience a resurgence of manufacturing not just in Columbia, but throughout the United States,” Brooks says. “How big? That’s hard to say. But I do think that companies are re-evaluating their strategies on where they manufacture products. In some cases, those strategies are supporting bringing production back to the U.S.”

Variety of goods

From hotdogs to water treatment systems, products made in Columbia are shipped all around the world. While many of the local plants are branches of national or international corporations, family-owned entrepreneurships have also contributed to the local manufacturing environment.

“For a relatively small number of companies, we’ve got a lot of variety here,” Brooks says.

Environmental Dynamics International manufactures systems for water and wastewater treatment. When Charles Tharp and his cousin Clark Campbell started the company in 1975, there were five employees including his wife. After the establishment of the U.S. Environmental Protection Agency in 1970, Tharp recognized the need for packaged solutions for wastewater treatment . Today EDI has customized its products and services for more than 6,000 projects on seven continents, including a research station in Antarctica.

Fred McCabe, vice president of operations, said the company started small and stayed relatively small until 2003, growing into $10 million in sales, and steadily to $30 million in 2011.

EDI has international sales offices in the U.K., China, India, Japan and Mexico and about 60 percent of its total sales are overseas. As it developed into a worldwide business, the company has faced challenges in transportation, currency fluctuations and political barriers.

EDI has international sales offices in the U.K., China, India, Japan and Mexico and about 60 percent of its total sales are overseas. As it developed into a worldwide business, the company has faced challenges in transportation, currency fluctuations and political barriers.

“We have 117 people to effectively cover the whole world,” McCabe says. “Also, we are 2,000 kilometers from the nearest port, so the costs associated with shipping from the U.S. to India, China, South America or any other country are substantial.”

EDI’s employees specialize in designing, producing, implementing, installing and maintaining the water and wastewater treatment systems. Human resources manager Sherri Redmon says the company’s emplpoyees must have skills in a variety of fields.

McCabe says that despite the global economic downturn from 2009 to 2011, EDI kept hiring. “We’re proud of being able to add people as a strategic decision to help our business expand in the long term,” he says.

From overseas to Columbia

From overseas to Columbia

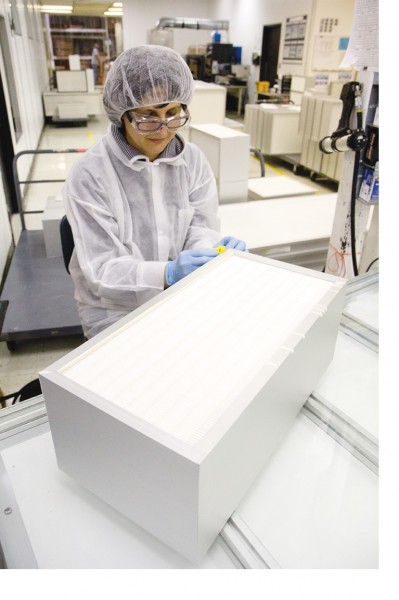

American Air Filter International has been a part of Columbia manufacturing since 1978 and is owned by Daikin Industries Ltd. of Osaka, Japan. The company’s 200 employees include production, supervising, management and maintenance workers.

The company hires people locally, but many have immigrated to the area from throughout the world. “We have people from multiple countries such as Vietnam, Malaysia, China, Nigeria, Ghana and Bulgaria,” says human resources manager Jeff Simon. “We are a melting pot.”

AAF International relies on Job Finders, an employment services agency, for temporary employees and then hires some of them as full-time employees.

Simon said it usually takes eight weeks to train a high school graduate or a student with a General Education Diploma to work on the assembly lines.

Another Japanese-owned manufacturer in Columbia is OTSCON Inc. Solely owned by Otsuka Koki, a multinational parking brake manufacturer company based in Japan, OTSCON established its manufacturing plant in Columbia in 1993 as the company’s only branch in the U.S. The Columbia plant produces parking brakes for Toyota, Honda, Nissan and Subaru. OTSCON currently has 238 employees, including 72 skilled workers, 136 semi-skilled workers and 30 administrative officers.

Kathy Cowan-Smith, director of human resources and risk management, says the OTSCON’s increase in employment is beneficial to Columbia’s economy. “In 2009, the auto industry took a downturn,” she says. “As people left for whatever reasons, we didn’t replace them. Now the economy is picking up, and we are back up to our capacity.”

OTSCON is looking for workers who are able to read detailed instruction, good in math and teamwork. Cowan-Smith said it’s not problem in finding the people they need. “We have a good workforce in central Missouri,” she says. “The work is not easy, but we really do not have a lot of difficulties in finding workers.”

National brands choose Columbia

The Kraft Foods plant in C

olumbia has made hotdogs for markets around the U.S. and Mexico since 1985. According to REDI’s research, Kraft’s local plant has 516 employees and ranks as the biggest employer in Columbia. Plant manager John Strotbeck says about 20 percent of the total workers are skilled workers such as line technicians, electricians and heat and refrigeration technicians.

“We’ve been able to find skilled people,” Strotbeck says. “It just takes a greater search to find them.” He adds that Kraft Foods was impacted by the recent economic downturn, but the plant’s total number of employment has been stable.

The Quaker Oats Company, owned by PepsiCo Inc., has manufactured and transported rice cakes to distribution centers since 1995. The food company

now employs 274 workers. Plant manager Rick Allio agrees with Strotbeck that it can be challenging to find workers with the right skills.

Watlow Electric Manufacturing, a multinational company with headquarters in St. Louis, chose to build a facility in Columbia in 1979. Watlow produces industrial heaters, sensors and controllers. The Columbia branch currently has 240 production workers and 82 administration employees. Human resources manager Beth Baileysaid skilled workers from operator technicians to tool-and-die makers are not hard to find or train. “With the unemployment rate still being high, we are able to fill in our positions fairly easily,” she says.

Columbia’s top 10 manufacturing employers

1 – Kraft Foods Inc. is an American multinational conglomerate that produces foods and beverages. The company has 516 employees at its factory in Columbia and supplies hotdogs to markets around the U.S. and Mexico.

2 – Schneider Electric, a multinational electrical energy company, produces circuit breakers at its Columbia plant. Based on Regional Economic Development Inc.’s research, the local factory had 309 employees in 2011.

3 – Quaker Oats owned by PepsiCo Inc., makes and transports quakes and large rice cakes to its distribution centers. The food company employs 274 workers.

4 – Watlow Electric Manufacturing Company, headquartered in St. Louis, is a multinational manufacturing company that produces electric heaters, sensors and controllers.Watlow currently has 240 production workers and 82 administration employees at its Columbia plant.

5 – OTSCON is owned by Otsuka Koki, a multinational parking brake manufacturer based in Japan. As the company’s only branch in the U.S., the Columbia plant has 238 workers.

6 – 3M, an international, diversified technological company, produces such items such as connectors, staplers, press-on optics and multitouch screens in Columbia. Based on Regional Economic Development Inc.’s research, there are 216 employees at the plant.

7 – American Air Filter International is owned by Daikin Industries, Ltd., based in Japan. The current 200 employers include production, supervising, management and maintenance workers.

8 – Dana Holding Corporation provides driveline, sealing and thermal-management technologies for passenger, commercial and off-highway vehicles. Based on Regional Economic Development Inc.’s research, its Columbia plant has 153 employees.

9 – Environmental Dynamics International is a local entrepreneurship focused on water and wastewater treatment systems. The company has grown from a five people in 1975 to an international company with 117 employees and more than $30 million in annual sales.

10 – Gates Corporation is a multinational manufacturer of industrial and automotive products, systems and components. Based on Regional Economic Development Inc.’s research, it has 107 people at its Columbia plant. In 1996, Gates became a wholly-owned subsidiary of Tomkins Ltd., which is a global engineering and manufacturing group based in Britain.